Continuing the saga from my previous posting, I bring you the photo-journal of the second month of my brutal summer adventures in the Shelter Island boatyards. Rather than re-introduce the situation, I’ll just jump in…

Canada Day brought intermittant rain, so mostly we just worked under the boat, sanding the overhead panels and getting our feet wet in the ever-growing puddles that pooled inexplicably under the boat instead of draining to the nearby sewer grate.

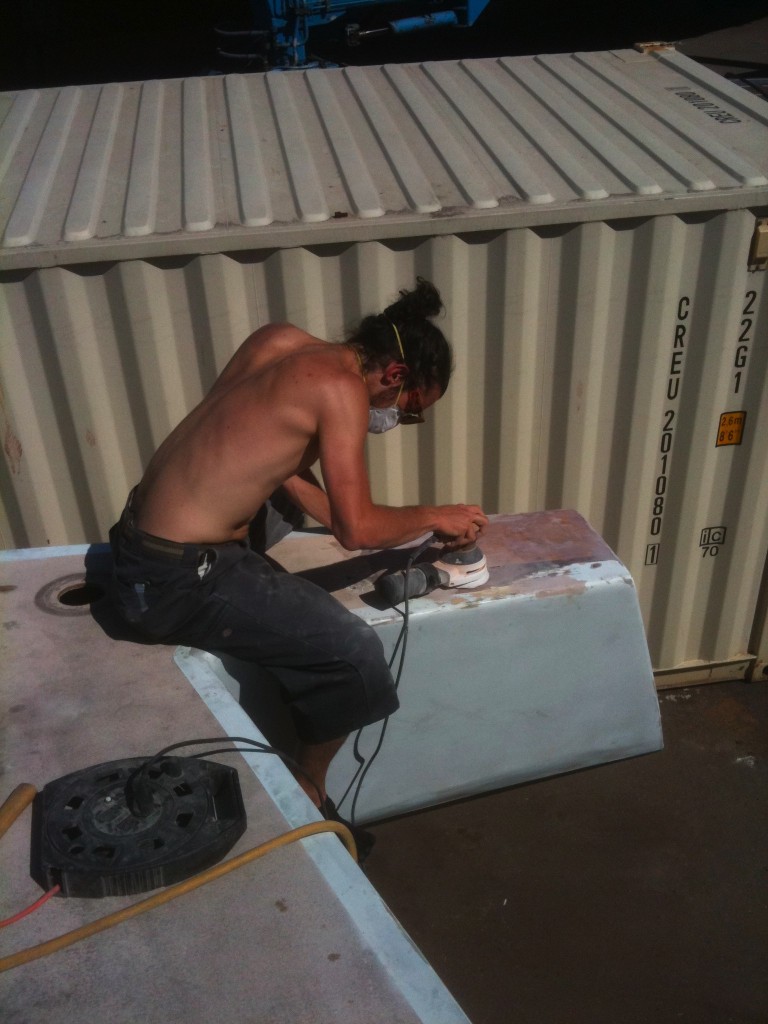

By the time the rains stopped, the hired boatyard labourer guy had finished grinding off the old bottom paint down to the reddish epoxy barrier coat, before disappearing for a few days – something that would become a recurring theme in the next few weeks. At least the labour was relatively cheap, and honestly the task of grinding off old bottom paint wasn’t something that DR and I were interested in tackling ourselves. Bottom paint on sailboats is “anti-fouling”, meaning it contains nasty poisons, so that things like mussels and barnacles and seaweed won’t be able to grow on the surface of the bottom of the boat.

Let me repeat that for good measure. Many things on worksites are poisonous, but usually the ‘poisonous’ property is secondary, ie. things like motor oil are lubrications that also happen to be poisonous. Bottom paint is poisonous because that’s what it was designed to be: poison. Grinding off old bottom paint throws literally pounds of poisonous dust into the air – no matter how good your respirator mask is, there is no way to make the job any more pleasant!

For the first few weeks, we cleaned up the worksite carefully every night at around 8pm or so, in accordance with the boatyard rules. By the end of July we were pretty much leaving the tools where they fell, and picking up each job the next day right where we left off.

After not showing up for several days (and getting kicked off the worksite following a yelling argument with the boatyard foreman), the hired labourer showed up and finished the job. Finally the bottom grinding was complete, and the bottom was primed with a grey epoxy barrier coat!

July 3rd brought ‘Sequential Circus 7‘, an electronic music concert/party/show that I (with a large group of dedicated friends) throw every six months. Fortunately we’ve been doing this for years now, and everyone really knows their jobs well… there were no hiccups and the show went off without a hitch. By all accounts, a great party.

In the starboard wing is a special locker for a horizontal propane cylinder. One of the critical points of keeping propane on a boat is ventilation; because a boat is watertight, and because propane is heavier than air, a propane leak can lead to a boat full of propane, silently awaiting a spark. More than a few boats have been blown apart by a bilge full of gas!

The locker must have holes in the bottom of it so that leaked propane can escape – however, some previous owner didn’t properly seal up the edges of the holes in the wooden floor of the locker, and as a result they rotted through. What looked to be a couple of small (ie a half-foot square) patches of rot turned into a 3’x4′ patch in the hull of the boat.

We found a bit of rot in the bottom of the line locker (a locker for ropes and anchors, in the port wing) as well, so we gutted and replaced a few panels in there. I wish I had a ‘before’ photo – the angled bit at the far corner of the locker used to be a pair of five-inch holes with an old corrugated steel elbow joining them; a tunnel to provide ventilation between the inside of the forward cabin and the port ama. The kicker: the steel elbow jutted out into the foot of the guest bunk, and would cut your toes if you kicked it wrong! I replaced it with a plywood enclosure and rounded and filletted all the corners, and added a vent grating to the inside of the cabin.

This project took a lot longer than expected – in this photo it looks complete, but it took another week of work afterwards, due to stupidity on my part. I had found a can of paint labelled ‘Neutral Base Coat’ in the old supplies that came with the original purchase of Tie Fighter, and I had also found a can of white epoxy paint, the same brand. I figured they’d be a good match for the heavy traffic of the line locker, a good base coat followed by a tough layer of epoxy paint. The funny part was that the “neutral base coat” was bright orange! I was a bit run down at that point, so I assumed that they must mean chemically neutral, and so I applied the base coat, waited a day, and then applied the white epoxy coat on top of that.

A week later, the white epoxy paint could still be peeled off with a fingernail, exposing the still-wet orange oil based paint below. I finally figured it out: orange paint is something that multihull sailboats are supposed to carry as a safety precaution… should the boat ever flip over at sea, you are supposed to paint ‘HELP’ or ‘SOS’ or something on the hull in orange to assist the rescue. I had used my rescue paint on my line locker, and worse, it was incompatible with my epoxy coat. I had to painstakingly remove all of the white and orange paint, using scrapers and solvents, before being able to paint the locker white again.

The next few weeks were the hottest days of the summer, and any job that didn’t require being in direct sunlight was infinitely preferred. We began gutting the salon.

I actually managed to pull Trent away from his insane summer schedule of school, work, and conference preparation. I think this was the only day he took off from his SIGGRAPH submission deadline…

Carrie also made it out several times to help out with the labour – though her biggest contribution by far was the loaning/renting of her Ford Bronco for weeks at a time, without which many of the jobs could simply not have been done. We must have made the trip to Home Depot two dozen times.

This photo shows the bottom of Tie Fighter in her ‘dress black’. The grey epoxy barrier coat first received a coat of red antifouling paint, then a coat of black – this way we tell how much of the antifouling has worn off just by the color of the hull.

The propellor, after having years of barnacles polished off with the angle grinder. Two large shaft zincs were later attached. I would have liked to swap out the propellor with a folding one, but we were unable to find one of the appropriate size and pitch within my price range while the boat was out of the water.

This photo shows the newly-repaired bow rail – the brown strip at the top of the hull, basically the edge of the deck. The rail was rotted when I purchased the boat, and was one of the first things I attempted to repair in the summer of 2009. In the year following, I learned so much more about woodworking and fiberglass that I tore out the previous year’s repairs and re-fixed the rail… properly this time. 🙂

This is the centerboard, tilted up so that the water inside could drain, while the fiberglassed repairs to the leading edge cured. You can see the multiple layers of barrier coat and antifouling paint, as well as the spots where the paint and even the fiberglass had worn completely through, exposing the wood underneath.

Another “tiny patch of rot”, at the base of the forward window. We learned pretty early on that it’s far simpler to take out an entire panel than it is to try to patch a section at a time. This was probably my favourite repair of the summer – by this point I had gotten the hang of the repairs, and this one went smoothly and very quickly, probably four days from start to finish.

The nasty part is that all of the dust you can see on the right side of the photo is powdered fiberglass. I always wear respiratory protection when working with fiberglass, but there’s just no way to keep the dust off of your skin. Taking on a job like replacing this window frame is resigning oneself to at least a week of itching.

Yet another “little patch of rot”… this one has never actually been finished, in fact. I still have to cut the replacement board and fit it into place. One of these afternoons…

The forward window fiberglassed in and partially faired – the next few steps are just adding fairing compound (epoxy thickened with a talc-like filling powder), spreading it out as smoothly as possible, waiting for it to cure, then sanding it down until the repairs completely disappear.

As a symbolic first step towards painting the boat, my signature ‘space invader’ stickers had to be removed. I have a few more of the stickers, and eventually they’ll be re-applied, but for now this was the end of the first chapter in the book of Tie Fighter.

The mast-head instruments never really worked. More specifically the wind speed indicator and the apparent wind indicator were completely smashed; you can see them lying on the ground in this photo. I looked into modern replacements, but a set of modern instruments can easily run well over $2000! I tracked down the company that made my instruments on the internet, and though they no longer make sailing instruments, they still had replacement parts in stock. A set of replacement masthead instruments ran me about $350. I also took this opportunity to replace the masthead ‘tricolor’ light with a combination tricolor and anchoring light.

The largest and most scary repair was the centerboard trunk – we had found signs of rot in the trunk walls, the sides of the housing for the centerboard. This section is often referred to as the “backbone” of the Searunner trimaran, and rot in here would eventually destroy the boat completely. I left this job for last, so that I would gain experience from all the other repairs and do the best job possible. The first step to fixing the centerboard trunk would of course be to remove the sections of the cockpit floor that had also shown signs of rot and would need to be replaced, and to gain access to the top of the trunk itself.

The new cockpit floor would be exactly like the old cockpit floor – 3/8″ marine-grade plywood, soaked in epoxy thinned with acetone and fiberglassed. This would be a very high-traffic area, completely exposed to the elements for many years to come, so we took our time to make sure that the replacement boards would done perfectly.

While I worked on the cockpit, I had DR painting the inside of the port ama. This was very possibly the harshest job of the summer, and DR was slightly more suited to the task than I, having a somewhat leaner frame than I as well as significantly more painting experience. I did not envy him the task, but he did a really great job on it.

In mid-July I had another friend come on nearly full-time to help with the boat; my friend James began staying at the boatyard with DR and I, and he proved to be a hard worker. Here he is scraping Sikaflex 291 out of the window frames… Sikaflex is a marine adhesive and sealant that stands up to pretty much anything. There’s a saying in the boating world: “That which Sikaflex and the Lord hath brought together, let no man tear asunder!”. Foul, foul stuff, nearly impossible to remove!

The biggest part of any boat repair job is the removal of the old materials – at some point we discovered the new Dremel ‘Multi-Max’ tool, which proved to be a magic wand for these sorts of repairs. In this photo you can see three of the four sections of cockpit floor removed; the fourth didn’t show any signs of rot, so we left it in place.

Also in this photo you can see the beginnings of the centerboard repairs! To my huge relief, the rot in the centerboard trunk was not very extensive, and we were able to cut out the rotted parts, soak the non-rotted exposed wood with propylene glycol to kill any remaining rot bacteria, soak it all in acetone to dry it out, brace the boards with fresh, sealed marine-grade plywood, and then finally fill the resulting gaps with epoxy thickened with powdered adhesive. I am confident that the repairs are stronger than the original construction.

Dan Ross completed the painting of the port ama, but with another upcoming heat wave staring us in the face, we decided that it would be better to have the boatyard labourer do the other ama.

The cockpit floors went in smoothly, and sanding would soon begin!

With a heatwave under way however we took any opportunity we could to work ‘indoors’ or underneath the boat… anything to stay out of the hot sun! The days were so hot that by noon we wouldn’t be able to think straight, and after a few near-misses involving power tools we decided that it would be best to try to take it a little easier during the hottest parts of the day.

The former mast step had been completely destroyed by rot, so I manufactured a new one by laminating four layers of marine plywood together with epoxy and then fiberglassing the whole thing over. I do not expect to ever have to replace this part again!

While the mast was down I decided that it would be wise to replace all of the internal wiring as well, and so over the span of two days I dragged over 250 feet of new wiring through the length of the mast, using tarred sailing twine given to me by my friend Kym Rich. This photo shows the knot used to secure the thick coaxial cable prior to dragging it through – if the knot were to let go, getting the cable through would have been a nightmare! This knot was subsequently covered in duct tape, and the system worked perfectly.

I had many visits from friends and family during this month. I tried to take photos each time, but I often failed and/or forgot. Here is my friend Emerson Tan and my baby sister Jen – five months pregnant in this photo – helping to remove chainplates.

The centerboard continued to be a project, one that could often be worked on during hot periods of the days, and so many hours of grinding and patching later it was nearly complete. This photo shows the board cleaned and shining in the sun.

Prior to painting, all of the former anti-skid paint had to be removed. Anti-skid is paint that has a rough texture – often it’s as simple as adding regular beach sand to the paint, but in the case of my boat it was a little more uniform. Sanding the anti-skid proved to be incredibly time consuming, and using the angle grinder was delicate work that often caused scarring of the fiberglass underneath. In a stroke of luck, we discovered that methyl-ethyl-ketone (MEK) solvent dissolved the antiskid paint, and after flailing for days with sanders and grinders, Chad Taylor and I took off all the antiskid in an afternoon with solvent and hand scrapers.

This photo shows the stripped wings, ready for priming and painting. Or at least we thought so, but as it turned out we had many days of sanding left before we could paint…

The hatches on Tie Fighter stand up about two inches off the deck, which is more than enough to catch on a wave coming over the decks. A big enough wave could tear a hatch open, which could end pretty badly under rough conditions, and so each hatch has a pair of wedge-shaped blocks of teak to deflect those incoming waves. I had gone to one of the boatyard shops looking to purchase a little block of teak for the top of the binnacle, and they offered to do all of my brightwork for not much more! The block of teak I purchased – the square piece at the top of the photo – was $40 finished, but to have them refinish all of my teak was only another $20, so I jumped at the chance.

Another “tiny spot of rot” was at the top of a very important bulkhead in the forward cabin, where the stay for the staysail attached. The former attachment hadn’t been sealed well, and a leak had been patched over from the inside… which means that the leak itself wasn’t repaired, just masked. A large chunk of the bulkhead had to be removed, and the repairs had to be *strong* – this four-inch thick laminated plywood brace was the final answer.

The crossbrace was carefully sized and finally bolted into place with another twelve 1/4″ bolts and lots of thickened epoxy. This marked the end of the rot repair projects!

Now that the repairs were pretty much complete, the next stage began in ernest – sanding and fairing every square inch of the boat, in preparation for painting. The sheer magnitude of this task was staggering – painting a large sailboat is a huge task, but painting a large trimaran is three times as much work!

Around this time, my friend Jesse came out to start helping with the boat repairs as well. Jesse brought his experience working at an automotive body shop to the table, and his attention to detail made a huge difference in the final project. At this point, each day I expected the boat to be finished “within a week”, and each week I realized that it would be at least another week of hard labour before we’d be even close to finished.

The end of July found us still hard at it; I was beginning to lose my confidence, and my wallet was significantly lighter than I had expected it to be at this point, but I was still confident that the end was nearing and that I’d yet have a great summer sailing adventure. At the very least, I’d have a few hot summer nights sitting at anchor in English Bay surrounded by friends, making music on the water, right…? Little did I know there would still be another solid month of work before the boat would even be back in the water, and another two months after that before she would sail away under her own power…